- Vacuum Packaging machine

- Case Erectors

- Labeling Machine

- Shrink Wrapper

- Carton Sealer

- Strapping Machine

- Battery Strapping Tool

- Strapping Tool

- Palletizer

- Wrapping Machine

- Carton Packer

- Packing Line

- PP/PET Straps

- Stretch Film/Shrink Film

- Conveyor

- Cartoning Machine

- Robot

- Vertical Packaging Machine?

- Tea/Coffee Bag Vffs?Machine

- Filling and Capping Machine

- Can Filler Seamer Machine?

- Full Automatic Can Unloader?

- Pasteurizer?

- Pre-mixer?

- Blow Molding Machine?

- Bottle Washer?

0086-571-87978016

0086-571-87978016 info@youngsunpack.com

info@youngsunpack.com

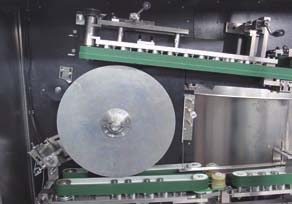

| YLP Bottle Unscrambler | |

YLP bottle unscrambler is composed of carrying bottle part, bottle arrangement turntable, main bottle arrangement part, electronic control unit and pneumatic device. A large amount of disorganized bottles is involved in bottle arrangement turntable, which is sent by carrying bottle part, and then conveyed to bottle arrangement part by the belt so as to the bottles can be stood and transferred to the user’s conveyor in an organized way. Bottle storage part can store a great number of bottles and is able to convey the bottles to bottle arrangement turntable. The speed of conveyor line can be adjusted by potentiometer of electrical box. Motor on and off can be controlled by photo electricity, which is external set on the cover of turntable. Applicable bottle:The bottle mouth and membrane line should be flat.The deviation of the bottle mouth should be less than±0.25mm.The deviation of the bottle height should be less than ±0.2mm. Applicable bottle material:HDPE/PP/PS etc. |

|

| Main Technical Data: | |

| Standard capacity: | Depending on the bottle size |

| Qualification rate: | ≥99.5% |

| Bottle height range: | 80~280mm |

| Bottle dia range: | φ40~φ85mm |

| Total power: | 3.16Kw |

| Running power: | 60%-80% |

| Air pressure: | ≥0.6MPa |

| Air consumption: | ≥0.8m3/min |

| Power supply(optional): | 3+N+PE 50Hz 380/220V±10% |

| Carrying bottle part size: | L2100×W1100×H1600mm |

| Machine dimension: | L2500×W2200×H1600mm |

| Machine weight : | 800Kg |

| According to different characteristics of products, the capacity will be different. | |

| Main Configuration: | ||

| Reducer: | Meiwa | |

| All low voltage electrical parts: | Schneider | |

| Warning light ,button and switch: | Siemens APT | |

| Touch screen: | Siemens/YOUNGSUN | |

| PLC: | Siemens | |

| Inverter: | Schneider | |

| Parameters and functions are subject to change without further notice. | ||

| Equipment Structure: | ||

| Main working process: | ||

| 1.Automatically feeding the bottles | ||

| 2. Bottle arranging | ||

| 3. Pneumatic output the bottles | ||

| Main frame: | ||

| 1.High quality stainless steel plate, stanchion, supporting unit, which is in a quality of good mechanical intensity. | ||

| 2. The machine adopts enclosed design | ||

| Driven system of the turntable: | ||

| 1. The main motor is controlled by frequency converter and the speed can be adjusted within production capacity | ||

| 2.Gear driven system can transfer the power to the running part | ||

| Pneumatic system: | ||

| 1. Low pressure protector, which guarantee the air pressure of the system | ||

| 2. Integrated electromagnetic valve | ||

| Electrical control system: | ||

| 1. High performance PLC, display various controlling information, status inspection information and warning information | ||

| 2. Humanized operation interface and display warning information timely | ||

| 3. Emergency stop button is set in necessary parts |